Introduction

Mechanical engineering student at Queen’s University with a passion for entrepreneurial ventures and making the world a better place.

Personal Achievements

Below is a list of projects I have completed that are worth sharing. They taught me firsthand about business, leadership, teamwork, problem – solving, and much more.

Commercial/Non Profit Ventures

Amazon E – Commerce (2023-2024)

- Successfully launched two Amazon stores, GoodsMansion and Product Haven, using Amazon’s FBA program in partnership with my first-year university roommate.

- Achieved $9,300 USD a month in revenue.

- Led a team of 10 part-time employees tasked with market research.

- Increased ROI by 300% through data-driven campaign optimization and price experimentation.

- Conducted product research using Helium 10 and sample tested over 15 products to minimize risk and achieve quality.

JASCI Services (2020-2023)

- Operated a local service company named JASCI Services with three friends from middle school during COVID-19.

- JASCI offered no-contact services such as lawn care, grocery shopping, virtual tutoring, snow shovelling, and more to the West Scarborough region of Toronto.

- Employed and trained a team of five employees once a stable client base was established.

Raising Money for Charity Through Video Games (2021)

- Implemented e-sport charity tournaments online during the COVID-19 period as co-president of the Victoria Park Gaming Club.

- Oversaw a total of 5 tournaments, engaging 110+ participants and raising a total of $300CAD towards The Ocean Cleanup North Pacific Foundation, Ocean Conservancy, Canadian Association for Suicide Prevention, North York Harvest Community, and the Canadian Red Cross.

- Ensured tasks from every sub-team were completed on schedule and that team accounting was done correctly.

University/Extra-Curricular Projects

Queen’s Aerospace Design Team (QADT) (2022-Current)

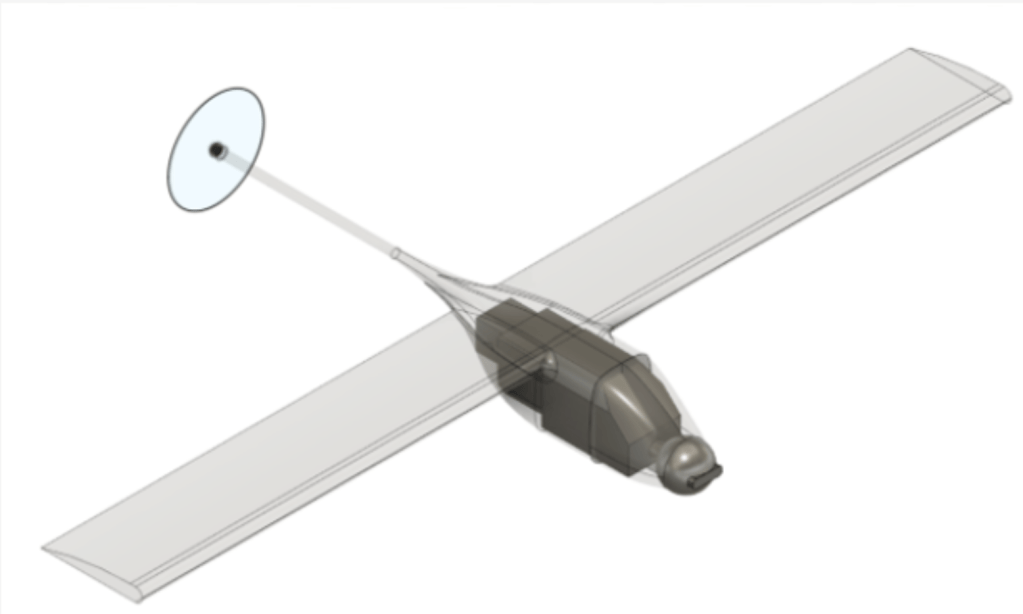

- Collaborated in a team of four to successfully design and optimize the 2024 competition aircraft.

- 2024 competition aircraft (Night-fury) built using fully in-house carbon fiber fabrication.

- Achieved a versatile flight envelope of 12m/s to 25m/s.

- Above features the optimized Clark Y airfoil for the 2024 competition aircraft.

- Reduced drag of the 2025 competition aircraft by 7% through implementing a blended wing design and adding Python-based optimization into our design iteration.

APSC Design Courses at Queen’s University

- APSC 200 Design Project (2024):

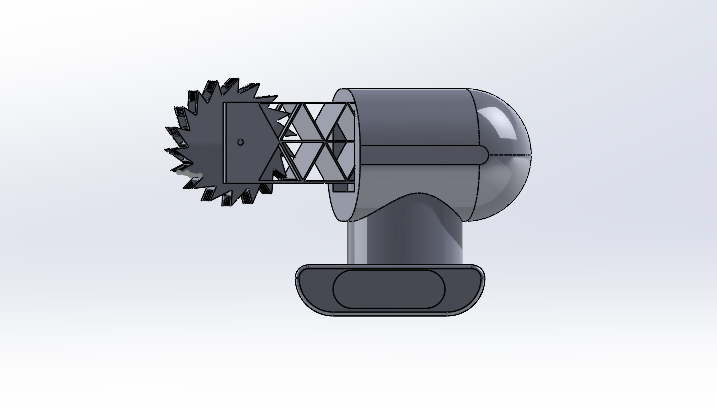

Collaborated in a team of 5 to develop a detailed mechanism for mining precious minerals on asteroids presented for the Queen’s Mining Society. - Identified 162173 Ryugu as the optimal mining candidate by analyzing orbital eccentricity, Earth proximity, and projected $30B profit potential.

- Developed a bucket wheel mining system with a dual-conveyor “sandwich” configuration to secure materials in low gravity, improving efficiency and transportability.

- BOM featured: Conveyor Belts – 12 x kevlar sheets (high tensile strength, lightweight, temperature resistance). Storage System and Support Structures – 2300kg of Al-Li alloy (10% weight reduction). Cutting edges – 24 x diamond incrusted blades 150mm cutting edge (precision cutting and longevity).

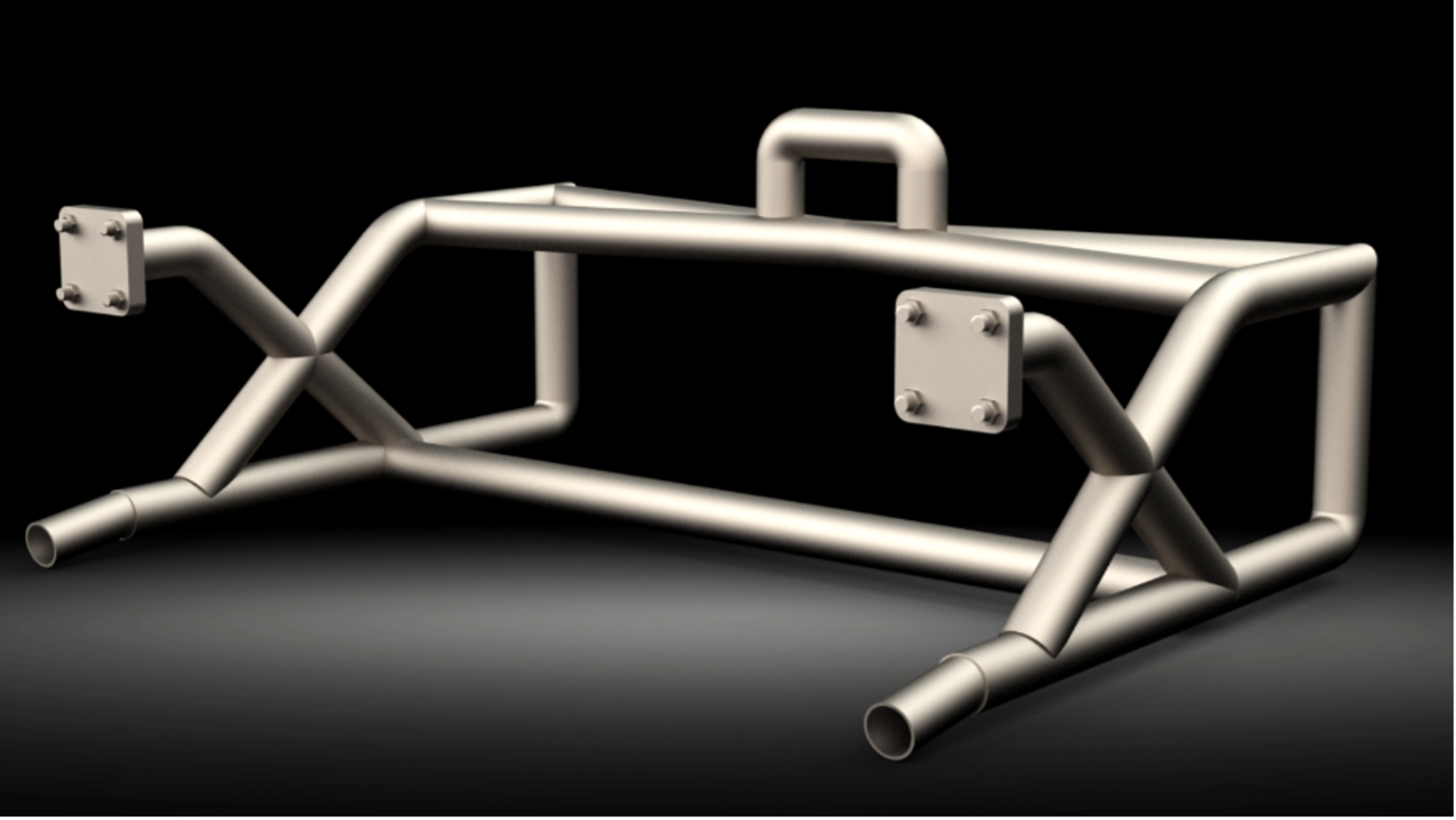

- APSC 103 Design Project (2023)- Queen’s Formula SAE: Collaborated in a team of six to develop a rear subframe design for the Queen’s Formula SAE’s 2024 season.

- Created three initial 3D designs in SolidWorks with detachable subframes; selected the final design using weighted evaluation matrices for weight, stiffness, strength, manufacturability, and cost.

- SolidWorks FEA revealed that rearmost vertical tubes will buckle under 2300N per suspension nodes, above target of 1500N.

Mechanical Engineering Internship Experience

A list of technical skills I developed while working at Brumar Engineering LTD as a summer mechanical engineering intern.

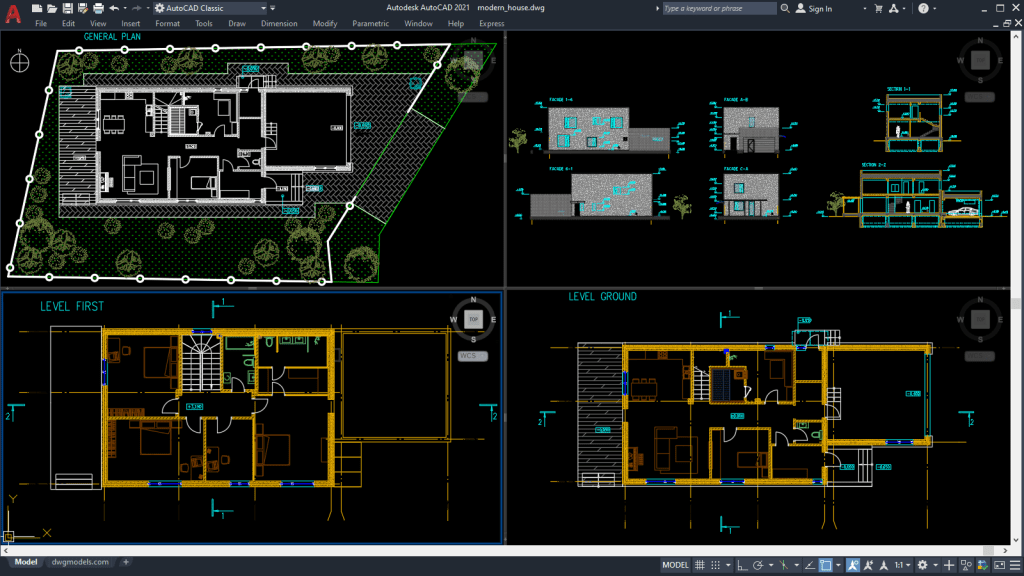

Ability to Efficiently Operate AutoCAD

Successfully utilized AutoCAD to produce building HVAC and plumbing drawings, as well as schedules, for the Orlando Corporation, Rice Group, and private building owners. Original architectural CAD drawings were used to produce backgrounds for the HVAC and plumbing drawings. HVAC and plumbing components were selected based on ASHRAE standards and economic considerations for the client.

Ability to Compute Load and Infiltration Calculations Manually or Using the Hourly Analysis Program (HAP)

Accurately computed building load (heat loss) calculations for the Orlando Corporation, Rice Group, and private building owners. Parameters such as window area, door area, wall area, and insulation R-values were successfully measured using building reference CAD files and other resources. These parameters were then inputted into heat loss equations or the HAP to calculate the load.

Plumbing Design and Safety

Accurately computed gas pipe sizing and invert calculations for the Orlando Corporation, Rice Group, and private building owners. ASHRAE standards were used for gas pipe sizing. Invert calculations were conducted to ensure safe clearance between sanitary piping and storm piping crossings.